It only takes one smudged barcode or a label that slips off to throw an entire production line into chaos. Products become untraceable, recalls get expensive, and compliance fines start stacking up. Customers lose trust when they can’t rely on accurate identification, and once that trust is gone, it’s hard to win back.

Traditional labels simply can’t keep up. They peel, fade, or get destroyed by heat and chemicals. Every replacement costs money, every reprint slows production.

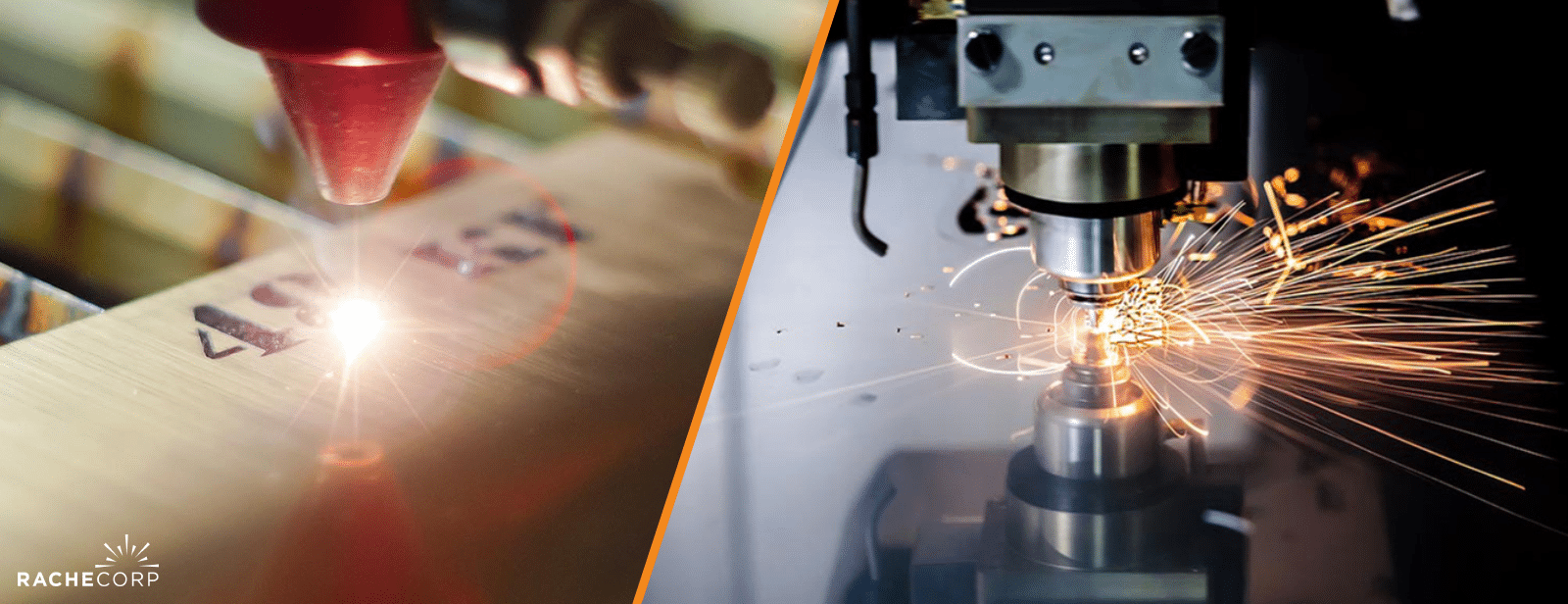

Laser marking fixes the problem at its core. Instead of sticking something onto a product, manufacturers engrave permanent, high-contrast marks that stay readable for the product’s entire lifecycle. It’s precise, durable, and built for the traceability today’s industries demand.

Also Read: CNC Milling vs. Laser Cutting: Pros, Cons, and Best Uses

Table of Contents

Understanding Traceability in Manufacturing

Traceability is more than just tagging parts. It’s about having a reliable way to track each product from start to finish.

What Traceability Means in Today’s Supply Chains

Modern supply chains are global and complex. With so many steps from raw materials to end users, traceability provides accountability. Every part can be tracked, every error can be identified, and every product can be verified as authentic. For regulated industries, this level of visibility isn’t optional.

Why Manufacturers Can’t Afford Traceability Gaps

One unreadable label can mean losing track of thousands of products. A missed scan might send faulty parts into the market. Beyond the fines and recalls, the biggest hit is to customer trust. Traceability gaps leave brands open to scrutiny, which is why more companies are turning to permanent solutions.

Traditional Labeling Methods: Strengths and Shortcomings

Labels have been around for decades, but their limitations are becoming harder to ignore.

- Common Options: Inkjet printing, barcodes, stickers, and RFID tags are fast and affordable, making them practical for short runs or products with limited shelf life.

- Environmental Limits: Heat, moisture, abrasion, and chemicals can wipe out a label. In industries like aerospace or healthcare, losing an identifier is more than inconvenient; it’s dangerous.

- Hidden Costs: Consumables like ink and adhesives need constant replacement. Misprints and re-labeling waste time and money, with costs adding up fast.

Introduction to Laser Marking Technology

Laser marking offers a smarter way forward for traceability.

What Is Laser Marking?

Laser marking uses a beam of light to create permanent identifiers directly on the surface of a product. Since it’s a non-contact process, there’s no ink or adhesive to wear out. The result is a sharp, precise mark every time.

Types of Laser Marking Techniques

Manufacturers can choose methods based on their production needs:

- Engraving: Creates deeper cuts for highly durable marks.

- Etching: Produces shallow, fast marks.

- Annealing: Heats the surface for oxide-based markings.

- Carbon Migration: Alters carbon in metals for high-contrast identifiers.

Materials Suitable for Laser Marking

Laser marking works on metals, plastics, ceramics, and glass, making it useful for aerospace, automotive, electronics, and healthcare industries.

Why Manufacturers Are Choosing Laser Marking Over Labels

Laser marking outperforms traditional labeling on every key metric.

Permanence and Durability

Laser marks don’t peel or fade. They withstand heat, abrasion, and chemicals, which means the code stays readable for the entire life of the product.

Precision and Readability

Lasers can engrave codes so small they fit on components the size of a fingernail. These high-contrast marks remain sharp and scannable, even under magnification.

Cost Efficiency in the Long Run

The equipment investment may feel bigger at first, but there are no consumables to buy later. Eliminating inks, labels, and adhesives saves money with every batch produced.

Speed and Automation Integration

Laser systems keep up with high-speed production lines and can be integrated with automation systems for consistent results without slowing operations.

Industry Applications of Laser Marking for Traceability

The benefits of laser marking stretch across industries.

- Aerospace & Space Manufacturing: High-precision laser marking ensures aircraft and spacecraft components remain identifiable under the toughest conditions.

- Automotive Industry: Permanent identifiers for engines, safety systems, and electronics support recalls, compliance, and long-term reliability.

- Commercial & Industrial Manufacturing: Scalable laser cutting, engraving, and welding deliver durability and precision for heavy machinery and metal parts.

- Medical Device & Healthcare: UDI-compliant marks withstand sterilization, ensuring traceability and patient safety for surgical tools and implants.

- Military & Defense: Deep engraving and welding solutions hold up in extreme environments, keeping mission-critical equipment traceable and secure.

- Packaging & Consumer Products: QR codes, barcodes, and permanent logos provide branding, authenticity, and traceability from factory to consumer.

- Solar & Renewable Energy: Reliable identifiers for solar panels, energy storage, and utility systems improve monitoring and long-term performance.

- Transportation & Logistics: Durable marking solutions keep rail, fleet, and shipping equipment traceable through years of wear and exposure.

Comparing Laser Marking vs. Labeling

Here’s how laser marking stacks up against traditional labels:

| Feature | Labels | Laser Marking |

| Durability | Can peel, fade, or smudge | Permanent, withstands harsh conditions |

| Cost | Ongoing consumables required | One-time equipment cost, no consumables |

| Compliance | Risk of unreadable labels | Always legible, even under stress |

| Flexibility | Limited size and detail | High precision, customizable codes |

Also Read: Complete Guide to Laser Solutions for the Industrial Sector

Common Misconceptions About Laser Marking

Some concerns about laser marking come from outdated information.

“Laser Marking Is Too Expensive to Start”

The upfront cost is higher than labeling equipment, but the long-term savings are much greater. Removing consumables and reducing downtime pays off quickly.

“It Damages the Product”

Not all laser marking methods cut deep. Techniques like annealing alter the surface without affecting the integrity of the product.

“Labels Are More Flexible”

Modern laser systems can mark everything from barcodes to logos. In many cases, they’re more versatile than traditional labels.

Choosing the Right Laser Marking System

Switching to laser marking takes some planning, but the results are worth it.

Key Factors to Consider

Think about the material, production volume, and required detail. A company producing millions of small plastic parts will need a different system than one marking steel components.

Integration With Existing Manufacturing Systems

Laser marking equipment can connect with conveyors, robotic arms, and production software. That means it can be added to existing lines without slowing output.

Partnering With a Trusted Laser Technology Provider

Choosing the right provider makes all the difference. At Rache Corp, we bring decades of experience in laser marking, cutting, welding, and helium leak testing. Our team guides clients from prototype to full production, offering training and support every step of the way. With Rache Corp, you always get proven expertise.

Conclusion

Traceability can’t be left to chance. Labels might be quick to apply, but they’re also quick to fail. Manufacturers need marks that last, and that’s why more industries are turning to laser technology.

At Rache Corp, we’ve spent over 30 years helping companies push the limits of what lasers can do. From cutting and welding to permanent marking, we’ve built solutions that meet the toughest production challenges. You don’t have to figure it out alone. Our team is here to bring proven expertise to your project.

Call us today at (805) 389-6868 to learn how we can help with your laser marking needs.

FAQs

How does laser marking differ from engraving?

Engraving cuts deeper into the material, while marking changes only the surface. For traceability, marking is usually the better option because it’s fast and precise.

Can laser marking be used on plastics?

Yes. Plastics are one of the most common materials for laser marking. The process creates high-contrast marks that stay visible without damaging the product.

Is laser marking safe for food packaging?

Yes. Many systems are designed for packaging materials and won’t affect the safety of the product inside.

How fast is laser marking compared to labeling?

Laser marking is just as fast as labeling, sometimes faster. Since there are no labels or inks to replace, production keeps moving without interruptions.