MEDICAL DEVICE MANUFACTURING SERVICES

Precision in Every Pulse: Elevating Medical Device

Manufacturing with Rache Corp’s Laser Technology

Rache Corp stands at the forefront of laser manufacturing solutions meticulously tailored to meet the distinctive demands of the medical industry. Our commitment to excellence as well as our extensive experience, sets us apart from other laser manufacturers. It has positioned us as trusted partners for medical device manufacturers seeking nothing short of perfection.

The medical industry is an arena where accuracy is not an option; it’s a mandate. The devices used to save lives and improve healthcare outcomes must be nothing short of perfect. It’s in this challenging environment that Rache Corp’s laser manufacturing solutions shine as beacons of precision. We understand that every fraction of a millimeter counts, and every component must meet the highest standards of quality.

Our laser solutions are purpose-built to meet these demands, making us an indispensable partner in the field of medical device manufacturing.

We Provide Manufacturing Services for:

- Aerospace and space flight companies

- Automotive manufacturers

- Electronics and technology firms

- Medical equipment manufacturers

- Military and defense sectors

- Industry Industries

- Product development companies

- Commercial businesses

Our Comprehensive Laser Solutions for the Medical Industry

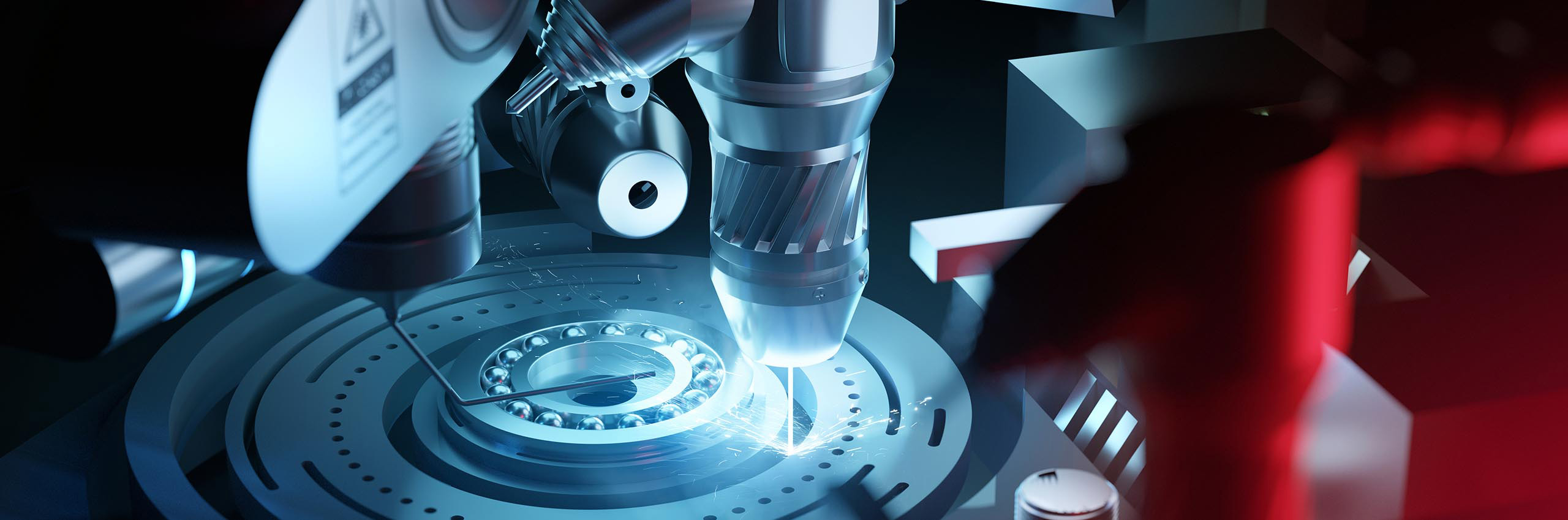

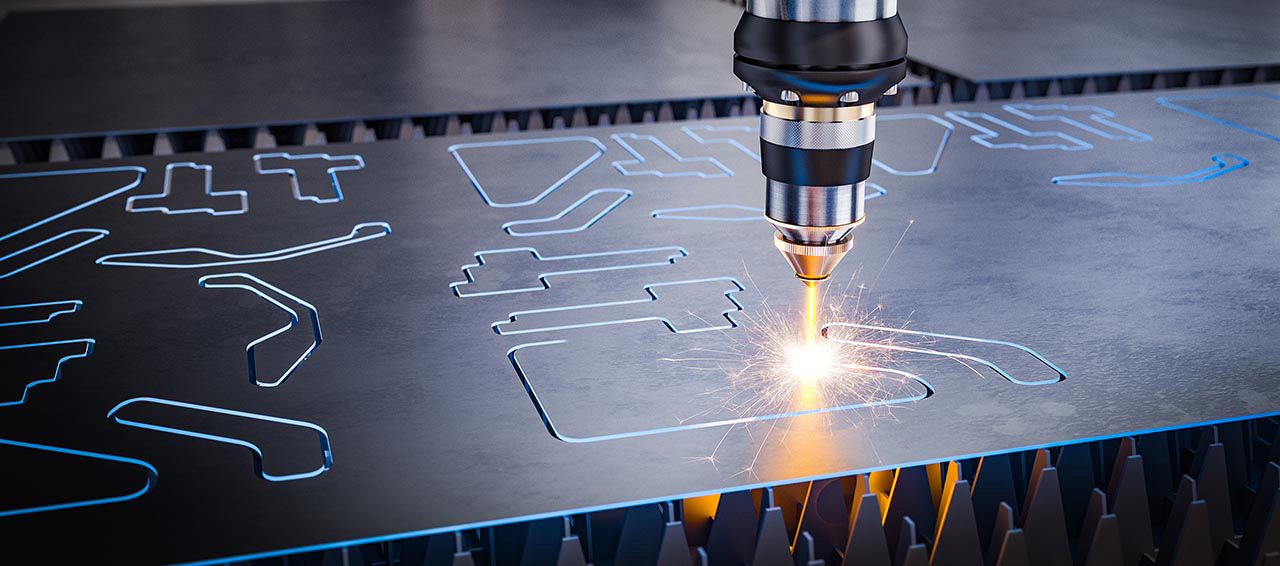

Laser Cutting for Medical Devices

In the domain of medical devices, precision and cleanliness are non-negotiable. Our cutting-edge laser-cutting technology excels in crafting intricate and precise components. It ensures that every cut is clean and aims to minimize the amount of burrs. Laser cutting allows the creation of precise 90-degree angles and complex designs with unparalleled accuracy at the microscopic level.

The precision of our lasers is unmatched, allowing us to create components with intricate geometries and tight tolerances. Whether it’s a critical part of a pacemaker or a delicate component of a surgical instrument, our laser-cutting technology ensures that each piece meets the highest standards of precision and cleanliness.

Laser Welding for Medical Components

The fusion of medical components demands nothing less than perfection. Our laser welding services deliver the highest degree of precision, guaranteeing that critical medical equipment operates flawlessly. It allows us to join dissimilar materials with utmost accuracy, making sure that the final product not only functions flawlessly but also adheres to the highest standards of biocompatibility.

Whether it’s a joint in a prosthetic device or a connection in a diagnostic instrument, our laser welding technology guarantees a level of precision and cleanliness that’s unparalleled in the industry.

Laser Engraving for Traceability

Our laser engraving technology shines because we know we are in an industry where traceability is essential. We ensure that critical product information, from serial numbers to specifications, is clearly and permanently marked, enhancing traceability and compliance. Our laser-engraved markings stand the test of time, providing durability and legibility.

But laser engraving is not just about marking products; it’s about ensuring the safety and accountability of every medical device that leaves our facility. We understand that lives are on the line, and the integrity of our markings is crucial. That’s why we invest in cutting-edge laser engraving technology that ensures every mark is clear, permanent, and tamper-resistant.

Laser Marking for Parts and Product Information

Medical devices require detailed product information for safe and effective use. Our laser marking solutions provide a precise and enduring means of conveying this information. This includes critical data such as manufacturing dates, specifications, and usage instructions. It is to ensure that essential information remains intact throughout the device’s lifecycle.

Our laser marking technology goes beyond merely adding information; it’s about creating a lasting bond between the product and its user. We understand that in a healthcare setting, clarity and durability are vital. That’s why our laser marking technology ensures that every mark is not only transparent and precise but also capable of withstanding the rigors of the healthcare environment.

Helium Leak Testing for Medical Devices

Integrity is non-negotiable when it comes to medical devices. We offer helium leak testing services to ensure that medical devices meet the most stringent quality standards. This non-destructive testing method identifies even the tiniest leaks and makes medical equipment safe and reliable.

We also understand that leak testing is a critical aspect of medical device manufacturing. Even the tiniest leak can compromise the performance and safety of a medical device. That’s why we employ helium leak testing, a method known for its sensitivity and accuracy. With this, we can detect leaks that are invisible to the naked eye, ensuring that every device we manufacture is free from defects.

Benefits of Laser Productions for Medical Device Manufacturing

Precision Beyond Compare

A Clean and Safe Approach

Versatility Redefined

Custom Solutions to Your Medical Innovation

At Rache Corp, we recognize that innovation in the medical field knows no bounds. Our laser manufacturing solutions are adaptable and versatile, catering to a diverse range of projects and applications within the medical industry. From the creation of pacemakers and hearing aids to surgical blades and biosensors, to medical implants, diagnostic devices, and prosthetics, we are dedicated to pushing the boundaries of what’s possible. We are eager to collaborate with you in bringing your medical innovations to life.

We understand that every medical device is unique, and that’s why we offer custom laser solutions tailored to your specific needs. Our team of laser manufacturing engineers possesses the knowledge and expertise to work closely with you in developing the perfect solution for your project. Whether it’s a complex medical device or a novel concept, we’re here to turn your ideas into reality.

Quality Assurance and Compliance

Adherence to rigorous quality standards and compliance regulations is supreme in the medical industry, and we take this commitment very seriously. Rache Corp holds AS9100 certifications, guaranteeing the highest quality standards in our manufacturing processes. Plus, we are fully UDI (Unique Device Identifier) compliant, enhancing traceability and accountability. Our dedication to quality assurance and compliance underscores our commitment to excellence in every facet of our work.

Why You Should Partner with Rache Corp

for Your Medical Manufacturing

Choose Rache Corp as your medical manufacturing partner for these reasons:

Expertise

Our laser manufacturing engineers have over three decades of experience, ensuring you benefit from a team with unmatched knowledge and proficiency.

Quality

We prioritize excellence and precision in every project, guaranteeing that your medical products meet the highest standards of quality and safety.

Customization

We take the time to understand your unique requirements and work closely with you to develop tailored solutions that align perfectly with your objectives.

Make the critical decision for your medical manufacturing endeavors by partnering with Rache Corp—a trusted and experienced team dedicated to your success.

Discover Long-Lasting Quality with Rache Corp’s Laser Solutions

In the continually advancing niche of medical device manufacturing, precision and innovation stand as the cornerstones of excellence. Rache Corp’s laser manufacturing solutions rise to the occasion, providing the accuracy, cleanliness, and compliance demanded by the medical industry. Our promise to eco-friendly practices, precise engineering, and relentless quality assurance makes us the partner of choice for those seeking excellence in medical device manufacturing.

Partner with Rache Corp as your medical laser manufacturer in Camarillo and surrounding areas. With us, precision and innovation converge to create lasting quality. Contact us today at (805) 389-6868 to explore how our laser solutions can elevate your medical device projects to success.

frequently asked questions

What materials can be processed with laser cutting in the medical industry?

Our laser technology is versatile and can be used on various materials, including: stainless steel, mild steel, carbon steel, blue temper steel, spring steel, aluminum, brass, red brass, titanium, nickel, nickel silver, copper, beryllium copper, gold, silver, platinum, tungsten, tin, phosphorus bronze, rhenium, molybdenum, Monel, Inconel, Kovar, Invar along with non-metal materials like acrylic, PTFE, neoprene, Kapton, thermal gaskets, foam, silicone, wood, plastics, rubber, ceramics, graphite sheets, and silicon thermal pads.

How precise is laser cutting for medical device manufacturing?

Laser cutting offers exceptional precision, with the ability to create intricate and complex shapes with minimal heat-affected zones. This precision is crucial for manufacturing medical devices with tight tolerances.

Are laser markings on medical devices permanent and safe for patients?

Yes, laser markings are permanent and safe for patients. Laser marking provides clear, precise, and durable markings on medical devices without compromising the integrity or safety of the product.

What quality control measures are in place for laser-manufactured medical components?

Quality control is crucial in the medical industry. Laser manufacturers often adhere to strict quality management systems like ISO 13485 to ensure that components meet the highest standards for safety and performance.

How can Rache Corp assist medical companies in laser manufacturing?

Rache Corp specializes in providing laser manufacturing solutions tailored to the medical industry’s needs, including laser cutting, laser welding, laser marking, and laser engraving. We work closely with medical companies to ensure precision, quality, and compliance with industry standards. Get in touch with us for a quote and how we can help you.

Why work with Rache Corporation?

We pioneered the method that makes laser cutting of thin metals possible.

“We were impressed with Rache Corporation’s laser cutting capabilities. Our parts have extremely difficult tolerances to meet. Rache had no problem meeting our specifications and requirements.”

— Alan W, Design Engineer