LASER ENGRAVING

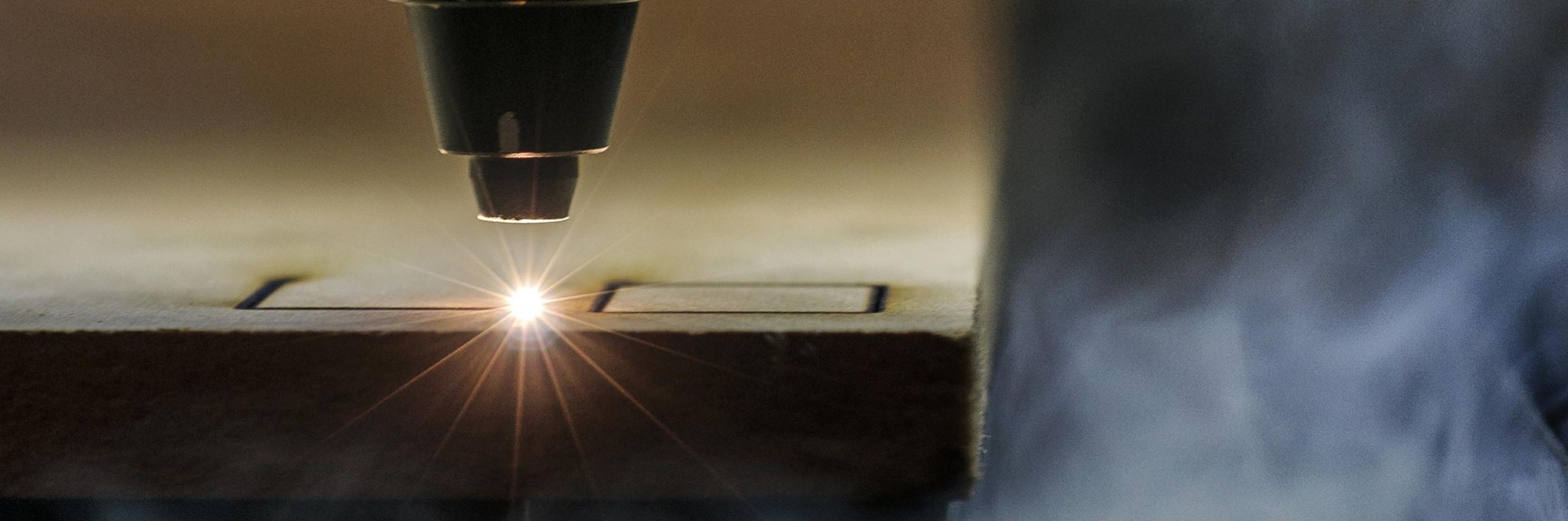

At Rache Corp, our high tech laser engraving services redefine excellence by seamlessly melding precision with innovation. With over 30 years of experience, we bring an unparalleled mastery of laser technology to every project across various industries needing laser engraving services in Camarillo and surrounding cities.

Whether you’re envisioning intricate designs on metals, plastics, synthetics, or more, our expertise crafts each mark with meticulous accuracy, leaving an indelible impression that resonates far beyond the surface.

Where Precision Meets Ingenuity

Our deep laser engraving capabilities are a testament to the fusion of art and technology. With state-of-the-art equipment and a team of skilled engineers, we craft engravings that meet the highest standards of precision and aesthetics.

Intricate Designs

From intricate patterns to delicate lettering, our laser technology can replicate even the most intricate details with exceptional clarity.

Variable Depth

Our laser engraving can create variable depths, adding dimensionality to your designs and enhancing the tactile experience.

Various Materials

Customization

What is Laser Engraving?

Laser engraving is a transformative technology that utilizes focused laser beams to create precise and intricate markings on a variety of materials. By directing a concentrated laser onto the material’s surface, the intense energy interaction results in permanent marks, ranging from text and patterns to intricate designs. This versatile technique accommodates diverse materials such as metals, plastics, and more, offering unmatched precision and customization.

The process involves directing the laser beam according to a predetermined design, which can include logos, serial numbers, text, barcodes, or complex patterns. This precision-focused approach offers distinct advantages over traditional engraving methods, as it can create intricate details and precise markings without the need for direct contact with the material. Laser engraving’s versatility and non-contact nature make it particularly well-suited for industries where durability, precision, and intricate designs are essential, including aerospace, medical devices, automotive components, and more.

Benefits of Laser Engraving Services Over Traditional Engraving

Precision

Enduring Quality

Environmental Friendly

Durability

Versatility

Streamlined Efficiency

EXPERIENCE THE PRECISION WITH RACHE CORP’S LASER CUTTING SERVICES

When you’re faced with challenging welding requirements, intricate designs, or the need for utmost precision, laser welding emerges as the optimal solution. Rache Corp stands ready to assist you in realizing these advantages and achieving exceptional outcomes for your unique projects.

Industries We Serve That Use

Our Laser Engraving Services

Aerospace and Space

Military and Defense

Automotive

Laser engravings elevate the automotive industry by enabling detailed markings on critical components, enhance traceability, quality assurance, and brand representation. From intricate logos to serial numbers, our engravings embody excellence in crucial components.

Medical

In the medical field, clear and permanent markings on devices and implants ensure accurate tracking, safety, and compliance. Our laser engravings contribute to patient care and regulatory adherence.

Industrial

In industrial applications, our Laser Engraving Services provide durable markings on parts, tools, and machinery. Streamlining processes and enhancing efficiency, our engravings withstand rigorous manufacturing demands.

Commercial

From electronics to consumer goods, our engravings enable precision markings for branding, serial numbers, and essential information. Enhancing brand identity and personalization, our engravings connect with consumers.

Why Choose Rache Corp for Your Custom Laser Engraving Services?

When it comes to laser engraving, Rache Corp stands as a beacon of expertise and innovation. With over 30 years of experience, we’ve mastered the art of precision engraving that leaves a lasting mark on various industries. Here’s why Rache Corp is your ultimate partner for laser engraving excellence:

- Precision Mastery: Experience unmatched accuracy with cutting-edge technology and our highly experienced engineers.

- Versatile Adaptability: From metals to plastics, our engravings excel across materials, offering endless creative potential.

- Tailored Excellence: Each project is unique; our customized engravings capture your brand’s essence.

- Diverse Industry Insight: Serving aerospace, defense, medical, automotive, industrial, and commercial sectors ensures versatile expertise.

- Lasting Quality: Our enduring engravings withstand wear, environmental factors, and time, ensuring lasting impact.

Contact Rache Corp for Precision Laser Engraving Services Your Industry Needs

Empower your projects with the artistry and durability that our laser engraving services offer. From intricate designs that captivate to enduring engravings that speak volumes, Rache Corp is your partner in pushing the boundaries of creativity and quality for laser engraving services in Camarillo and surrounding areas. Contact us today at (805) 389-6868 how we can help you bring your vision to life. Experience the precision, expertise, and distinction that set Rache Corp apart as your premier laser engraving solution. Your mark, magnified.

frequently asked questions

Do we supply the materials?

The client will almost always provide the art and materials.

Do you have order limits?

Orders are typically between 10 to 10,000 but case depending, we can do more or less.

Can laser engraving be used for text of different sizes and fonts?

Yes, laser engraving can accommodate text of various sizes and fonts. The precision of the laser allows for clear and accurate reproduction of text, whether it’s small and intricate or large and bold. Your laser engraving provider can work with you to ensure your desired text is accurately engraved.

Can laser engraving be used on curved surfaces?

Yes, laser engraving can be used on curved surfaces to create intricate designs and markings. Advanced laser engraving systems can adjust the focus of the laser to accommodate different surface contours, ensuring accurate and consistent engravings.

How does laser engraving differ from laser marking?

Laser engraving and laser marking are closely related techniques, but they serve distinct purposes. Laser engraving involves removing materials from the surface, resulting in distinct indentations or grooves that yield deeper and more prominent markings. Laser marking, on the other hand, alters the surface color or texture without removing material, resulting in subtle and surface-level markings. The choice between engraving and marking depends on factors such as desired visibility, material type, and intended application.

WHY WORK WITH RACHE CORPORATION?

WE HAVE DECADES OF EXPERIENCE AND WE BRING THAT HARD-EARNED KNOWLEDGE TO EVERY PROJECT.

Laser Drilling Materials Specifications

Laser Drilling Materials

- Aluminum

- Anodized Aluminum

- Brass

- Copper & Beryllium Copper (Be-Cu)

- Stainless Steel

- Cold-Rolled Steel

- Titanium

- Nickel

- Nitinol (Nickel-Titanium)

- Exotic & Hi-temp Alloys

- Kovar®

- Inconel®

- Monel®

- Delrin®

- PTFE

- Nomex®

- Acrylics (no Polycarbonates)

- Red Silicone

- Polyamides (PA)

- Polyimide, Kapton

- Black Kapton

- Molybdenum

- Invar®

- Platinum

- Phosphorus Bronze

- Gold

- Tungsten

Overcoming Challenges of Cutting KovarⓇ And Nickel Alloys

Rache Corporation Thin Kovar® Laser Cutting

Conventional machining techniques of Kovar® (ASTM F15 alloy) in thicknesses from .010” to .100” have always been a challenge. Nickel alloys harden quickly, and the high pressures that machining creates causes hardening and slows down the process. Tools have a tendency to plow through Kovar® rather than chip away at it and the material tends to gum.

Holes must be frequently cleaned to remove chips that will gall and machinists develop their own machining techniques and documenting the process is somewhat subjective.

When machining Kovar®, keeping the machined area cool is a must to minimize warping of the material. Diligent tool wear inspection is also a must. Drilling / reaming requires constant attention.

Sulphur in the cutting fluid may degrade the Kovar’s magnetic properties and could cause grain embrittlement.

.025” Thick Kovar®

Over 30 years ago, Rache Corporation developed a laser process that produces thin-metal shapes at a lower cost than conventional machining methods and cutting Kovar® is one of our specialties. Our electronic / microwave customers are pleased that they can now utilize this laser cutting option especially in the critical delivery pre-production prototype phase.