WHY CALL US?

When you’ve completed as many projects as we have you learn a thing or two.

Experience

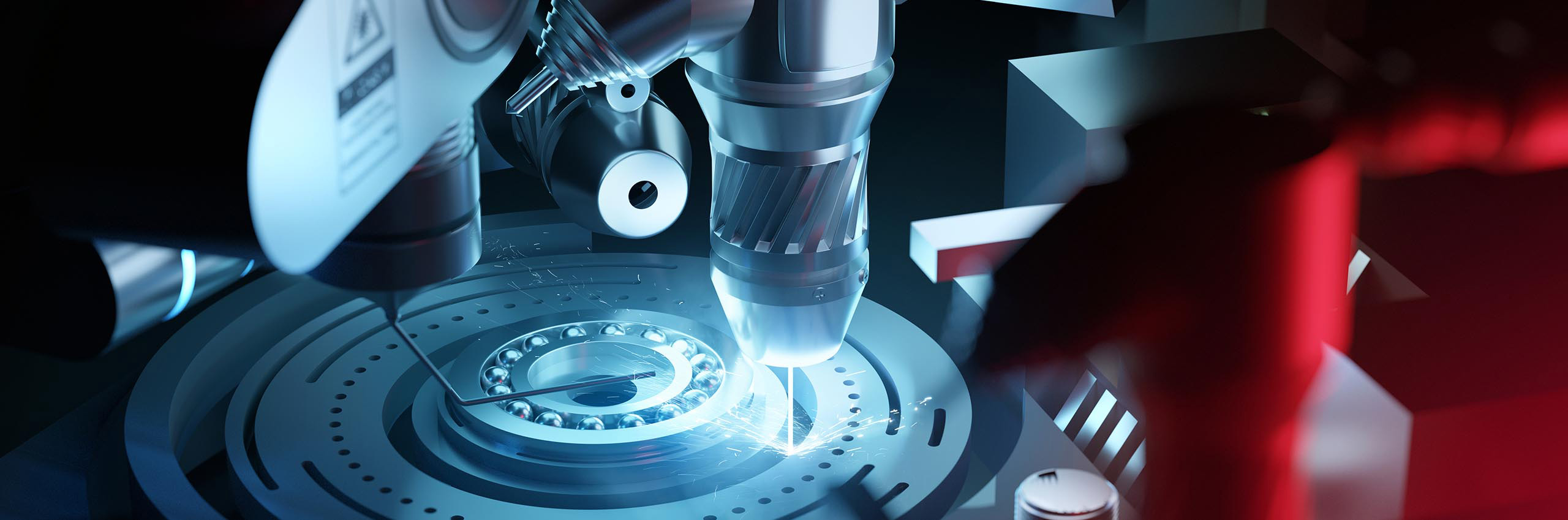

Here at Rache Corp. we have pushed the limits of what lasers can do by developing proprietary technology for customers with unique laser cutting, laser welding, and laser marking needs. When you partner with us you don’t have to do all of the testing and trials alone. You get a team that brings 30+ years of experience to every project.

One of the things that our clients love most about working with us is the value that we bring to the project as a whole.

VALUE ADDED ENGINEERING

Our experience gives us a unique perspective that helps us see opportunities that others miss.

We can offer suggestions that can:

- Reduce production cycle time

- Save on materials costs

- Minimize labor costs

- Increase product yields

Ultimately, our experience can save you time and increase your profit margins!

“Throughout our complicated R&D process, Rache engineers were willing and involved partners. We implemented several of their suggestions which resulted in cost reductions and processing time. Rache’s service is distinctive, they respond to our needs for short runs with quick turnaround, and support our full scale manufacturing requirements.”

— Carrie J, Vice President of Operations

Quality

Customers and their unique requirements are our primary focus.

We strive to meet or exceed all statutory, regulatory and QMS requirements, but more than that we are committed to enhancing customer satisfaction. We do this by making it a priority to understand the objective and requirements of every project, addressing risks and opportunities, and delivering the quality work and components to support each project toward success.

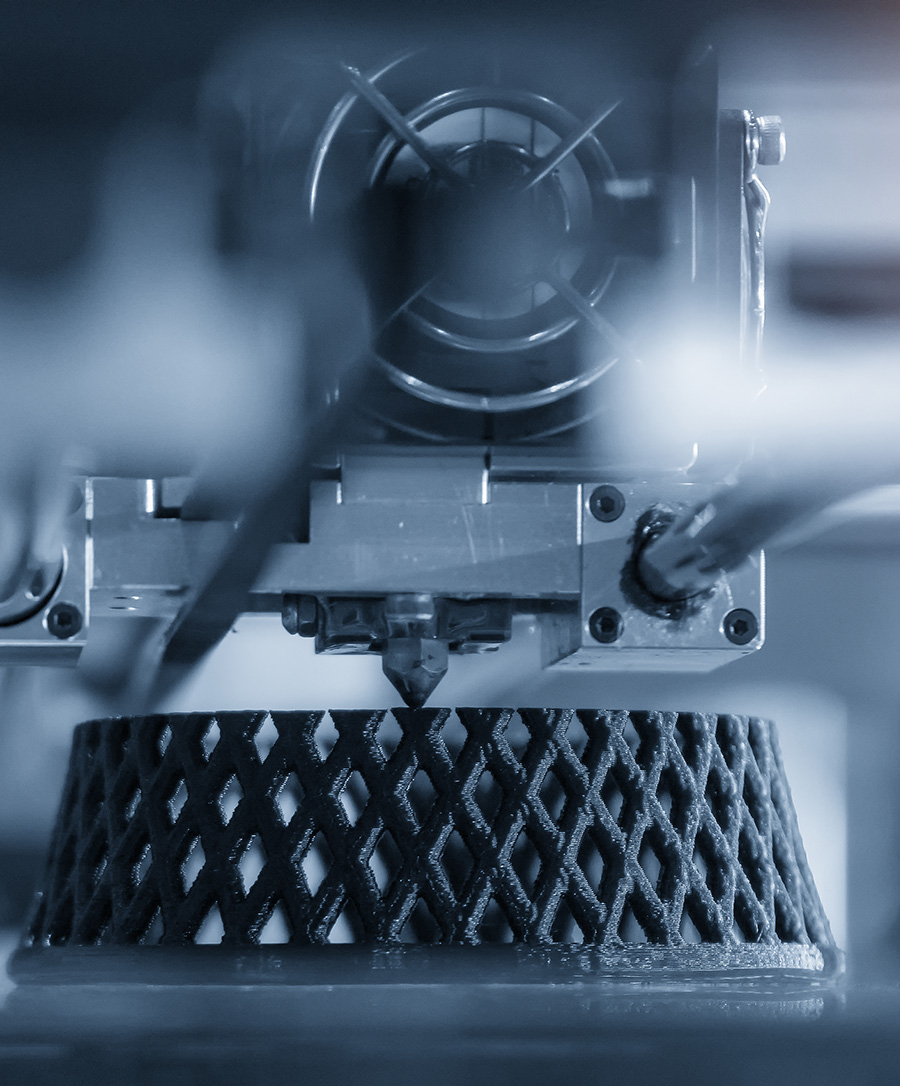

PROTOTYPING

prototyping is our specialty. It’s the first step in the production stage of your R&D process. We can help and we make it quick and easy for you!

- We stock many popular materials

- Our lead time is just a couple of days

- Plus, Same day service is available

Contact us today to request a FREE prototype!

Customers in the aerospace/space, military, defense, medical device, automotive, and commercial industries have come to trust us with their most critical projects.

FLEXIBILITY IN PRODUCTION

In addition to value added engineering and prototyping we’re flexible enough to make improvements and changes as needed throughout your production process.

We help move your project forward at every stage of the production process:

- Design validation and pilot production

- Quickly accommodate design changes

- Simultaneously fabricate multiple design variations

- Shorten product development cycle

- Quickly identify and resolve manufacturing issues to minimize production costs

- Facilitate Design for Manufacturability (DFM) process to ensure a smooth transition into production

“Rache participates in our R&D process. Rache engineers were able to perfect a marking method for powder-coated parts using variable laser speeds that met our quality specs. Had we tried the same project, I’m sure we would have ended up with a lot of scrap in-house. We don’t even want to consider looking for another vendor.”

— Scott L, Purchasing