Laser-cutting services are becoming indispensable in a wide range of sectors, including the business and medical industries. Because of their accuracy, versatility, and outstanding cutting efficiency, they have become prevalent worldwide. Moreover, laser-cutting innovation has dominated every sector over the previous several decades. This is why people become aware of its benefits, leading to a rise in the number of laser cutting service providers.

There are also various methods available in laser cutting; you only need to think about what type of laser cutting services best meets your demands. Delve deeper into laser cutting and its types.

What Is Laser Cutting?

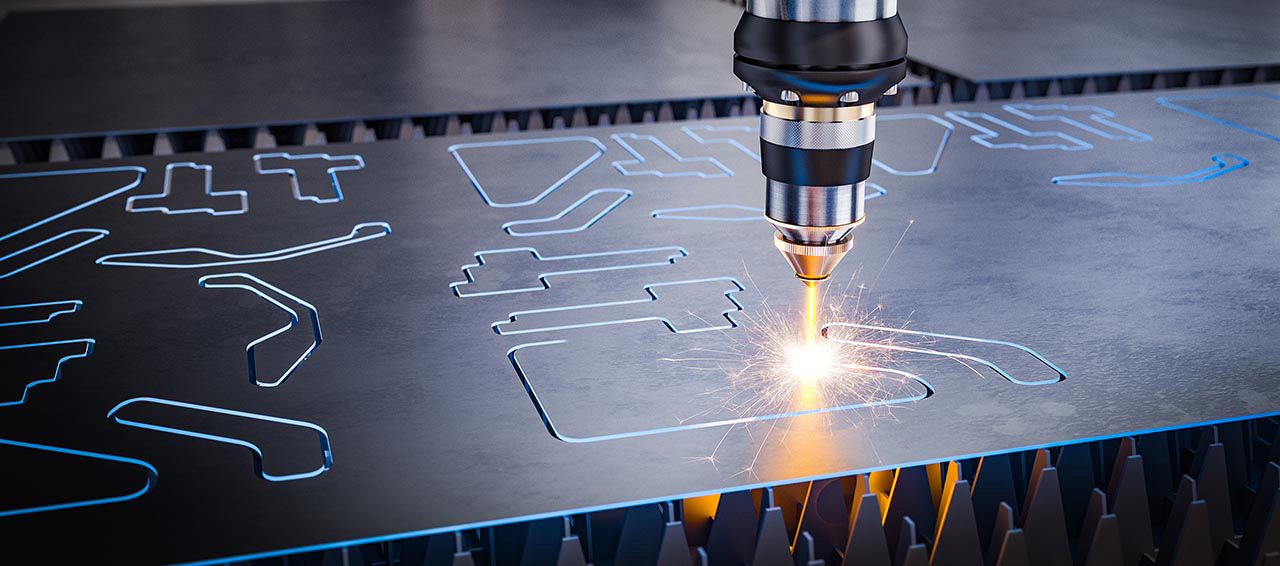

Laser cutting services entail a high-accuracy thermal technique that cuts, melts, or burns a material sheet using a high-power laser beam. It cuts and etches sheet material to the design specifications using a focused light beam. It can also produce intricate pieces without needing a customized tool and is suitable for a wide range of material kinds.

Moreover, because of its excellent reproducibility, the method is appropriate for each operation and low-to-moderate scale manufacturing. Laser cutting is very beneficial in the manufacturing of metals. Because of its great accuracy, dependability, and flawless finishes, it has been a solid favorite in medical equipment manufacturing.

Types Of Laser Cutting Service

The varieties of laser cutting services are classified based on the materials used in the procedure. Every material type took a different strategy and could be used in various industries.

Laser Cutting Metal

Laser cutting operations for all metallic substrates, such as bronze, brass, titanium, aluminum, and steel, are available in operational variations of up to 50 inches x 50 inches x 9.5 inches. Furthermore, metal laser cutting technology tolerates 0.002 inches for exact metal patterns. Various thicknesses and laser cutting procedures, such as laser drilling, sublimation cutting, fusion cutting, and flame cutting, are used based on the metal to achieve a robust and uniform surface along the cut edge.

Laser Cutting Plastic And Synthetics

Because the warmth-affected region is very tiny in comparison to other cutting technologies, laser cutting is also suitable for cutting plastics and synthetics. This feature enables laser cutting to provide better edges while reducing unnecessary extra finishing processes. Furthermore, laser cutting services in synthetics and plastics work in variations of up to 50 inches x 50 inches x 9.5 inches and tolerance levels of 0.002 inches.

Laser Cutting Wood And Paper

Because the method doesn’t apply mechanical power to the product, laser cutting is perfect for flexible materials such as paper and wood. This technique feature decreases the possibility of distortion in the finished component or product. Furthermore, adhesive labels, cardboard, plywood, MDF, veneer, and wood board are processed using laser drilling, sublimation, fusion cutting, and flame cutting operations.

Laser Cutting Organics And Fabrics

Laser cutting allows the creation of exact patterns and forms in cloth and organic materials. Furthermore, the method yields high-quality border trims with low material waste. Flame cutting, fusion cutting, sublimation, and laser drilling are some of the laser cutting and engraving options available for fabric and organic substrates.

Laser Cutting Methods

Manufacturers use various laser cutting techniques based on the material and size of their products. While the essential principles of the method continue to be the same, employing a focused beam to dissolve the substrate and assist gas in easing the cutting process, the variations change significantly. Various kinds include:

- Flame cutting: This method utilizes oxygen to eliminate molten material from the kerf. Moreover, when oxygen combines with the substrate material, an exothermic effect proceeds, which increases energy and speeds up the procedure.

- Fusion cutting: This method employs aid gases selected mainly for their lack of sensitivity to the substrate.

- Sublimation: In sublimation, the laser warms the substrate materials to the level of vaporization before blowing away surplus material using an inert assistance gas.

- Laser drilling: This is a procedure that uses laser beam pulses to drill holes in an object.

The Benefits of Laser Cutting Services

An array of variables contribute to laser cutting’s broad appeal. This comprises the precision and accuracy it provides, which gives significant benefits over other procedures. Laser cutting also ensures outstanding performance if clean cuts and smoother surface treatments are required, since the utilization of laser power to cut with a highly concentrated beam, allows for precise tolerances around the intended cutting zone.

Furthermore, since laser cutting is employed within precisely specified zones and does not require extra heat, substantially thinner parts of material may be operated on than with other procedures. The heat ranging from acute to a laser is also generally tiny, wherein the treated substance is less affected by bending or deformation caused by changes in its microstructure. Hence, unlike other methods, laser cutting services can generate complicated shapes with greater accuracy and tolerance.

Meta description:

Laser cutting services vary, depending on the materials used. To know the different types of laser cutting services, read this article.