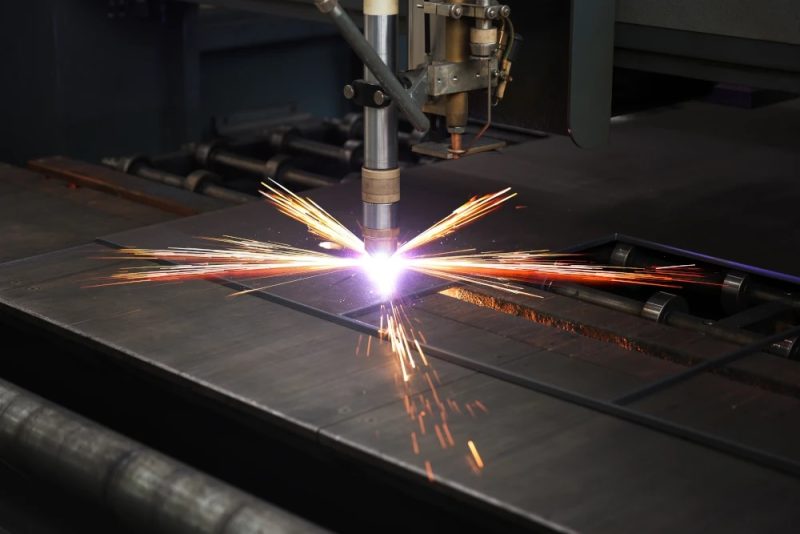

Metal laser cutting is used to cut metal parts into specific shapes and sizes. It uses a high-powered laser beam to cut through the metal, making it an efficient and cost-effective way to produce parts for various industries, giving it an advantage, but it also has some drawbacks. In this article, we’ll talk about the pros and cons of metal laser cutting so that you can decide if this technology is right for your project.

What Are The Advantages And Disadvantages Of Metal Laser Cutting?

While using a metal laser to cut is an effective approach to create various forms, it has pros and cons, just like everything else. The breakdown is as follows:

Disadvantages

- High Cost. The cutting process is expensive, and the amount of time it takes to produce a finished design depends mainly on the complexity of your material.

- More Complex. Metal laser cutting is also a lot more complex than other alternative materials due to the intricate nature of their design. Depending on the complexity of your design, it could take longer to do your project than you are willing to wait.

- Fire Hazard. In terms of safety, cutting metal with a laser can cause fires or explosions that could hurt workers and people nearby.

- Air Pollution. During the metal-melting process, water vapor and air pollutants are produced (the United States Laser Institute).

- Excessive Water Use. Metal requires much water to melt into liquid form before being poured into the mold and fashioned into chairs, buildings, and bridges. Each kilogram of metal requires 100 gallons of water. A kilogram of steel uses enough water to fill an Olympic swimming pool.

Advantages

- Delivers more control. This means less waste, fewer mistakes, and a better chance that the product will be successful.

- Quick Process. Metal laser cutting can produce smooth cuts in less than a second, compared to mechanical sawing or grinding processes.

- Make Intricate Designs. With this method, manufacturing by other methods, like 3D printing or bending cold-rolled steel sheets into shape, would be difficult or impossible.

- Uses Less Power. Cutting metal with a metal laser cutting equipment needs less heat than other lasers, making this technology attractive for industries that need to cut through lots of metal.

In general, metal laser cutters are used a lot in the design process because they can make high-quality products that are reliable and precise.

What Are The Limitations Of Laser Machining?

Despite its many benefits, it does have some limitations. These include difficulty in machining certain materials, such as rubber or foam, the need for highly specialized equipment, and the potential for heat damage to the material being machined. Additionally, laser machining can be costly due to its high energy consumption.

What Materials Cannot Be Cut With A Laser Cutter?

Laser cutters are powerful tools that can be used to cut various materials. However, laser cutters cannot cut certain materials due to their nature or composition. The following materials cannot be cut with a laser cutter because they will be damaged:

- Sharp materials such as metal and glass,

- paper/glossy paper

- cardboard

- thin cardstock

- metal foil/sheets-plastic

- film/sheets

- metal-copper wire-wood, and,

- motorized components that a laser beam can harm