Precision laser services are increasingly emerging as among the most effective options for numerous existing metal-cutting processes because of their amazing accuracy. Precision laser services provide cleaner edges than conventional processes, such as laser die cutting, water jet cutting, and turret punching. In addition, the edges are trimmed so perfectly that no additional procedures are required.

Furthermore, the degree of accuracy provided by precision laser services enhances the amount of complexity that may be made as well as material savings. Again, such accuracy and perfection are achievable at reasonable prices and without increasing run times. Learn more about precision laser services through this blog.

What Is The Precision Laser Process?

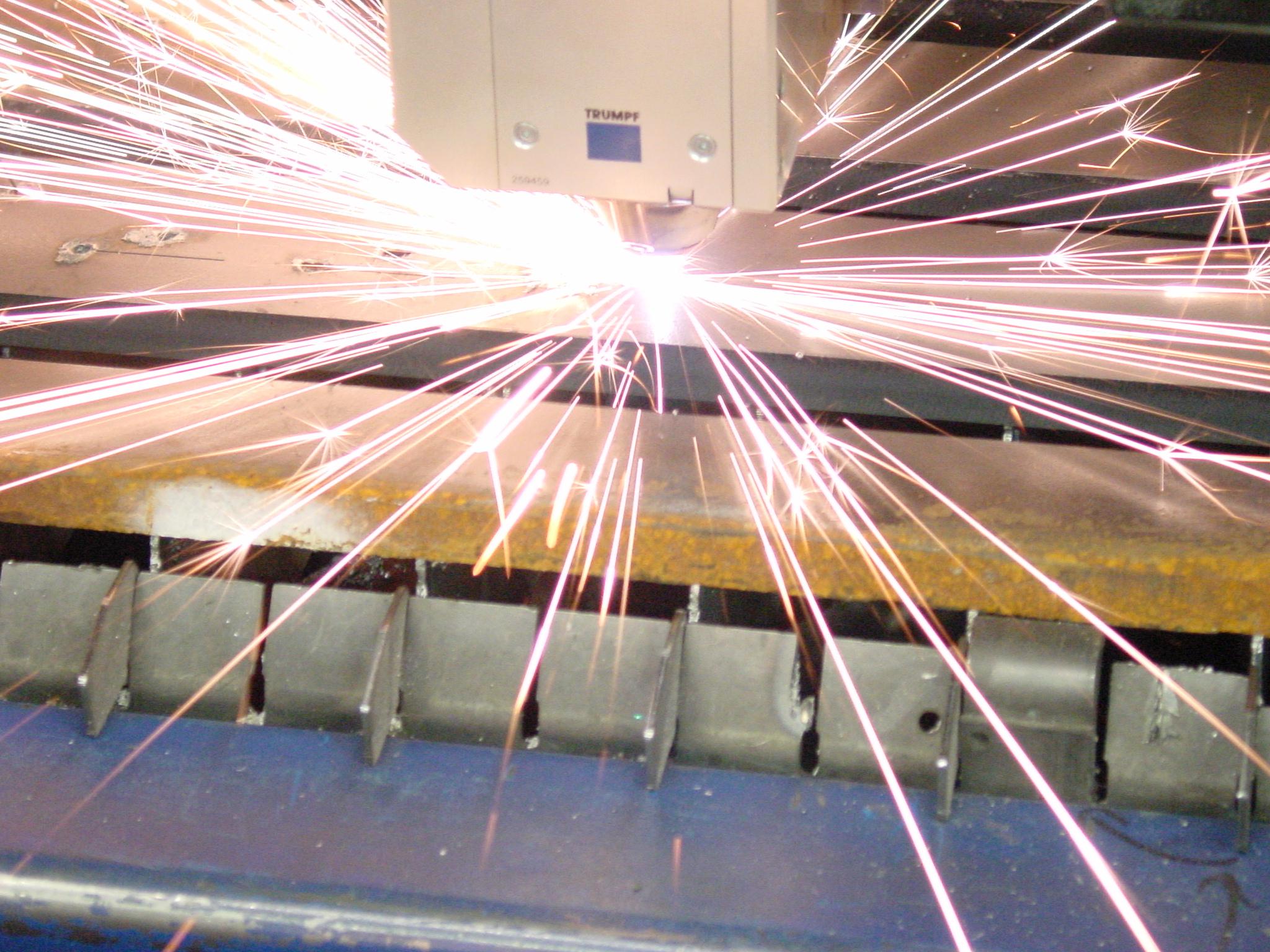

The laser cutting procedure occurs with your layout and conceptual ideas. After you have created it, you may make graphics or use any other 2D program to communicate the material to the laser. Utilizing the laser head, the laser cutter creates a high-powered laser beam aimed at the object. Based on the strength of the laser and the qualities of the material, the beam then dissolves, evaporates, or burns through it.

Moreover, a mobility control system or a specific programming method known as G-code is often used to regulate the laser’s motions. The G-code instructs the laser on where to travel and the amount of strength to utilize, allowing it to cut into material exceptionally accurately. A G-code file, for instance, may instruct the laser to proceed over a wooden piece in a straight path, creating millions of minor cuts along the route.

What Metal Fabrication Services Makes Laser Precision Offer?

Metal fabrication services on laser precision include:

Cutting Lasers And Turret Punch Presses

Precision laser services specialize in sheet metal manufacturing on various metal materials. Laser cutting or turret punching is the first stage in the metal process of production to create a final component or output. The quickness and precision of lasers and turret presses, such as CNC-enabled equipment, aid in maintaining a competitive advantage on component cost and lead to consistently excellent quality standards.

Metal Bending And Forming

Precision laser services’ metal bending and forming are furnished with cutting-edge fabrication equipment, such as CNC-controlled machines and automatic bending robotics. This machine uses European-style pressing brake tooling for more precision, extended tool life, versatility, and shorter set-up time.

Hardware Insertion

The hardware insertion features include presses with vast capability, most of which are fitted with automated feeds to boost efficiency.

Metal Deburring, Graining, And Polishing

The precision laser uses cutting-edge deburring or graining machines and a wide range of grinding and tumbling machinery to supply clients with scratch and burr-free products. The highly qualified technicians could manage every surface metal finishing demand, from grainy finishes to #8 mirror stainless.

Best Precision Laser Tool

Precision laser tools have grown into compact, efficient, and simple-to-use instruments that can quickly take your crafts and ideas to life. These devices are lightweight and user-friendly and can cut anything from wood, leather, and glass, to metal. The best laser tools for effective precision laser services are listed below.

Glowforge Plus

Glowforge Plus is a brilliantly crafted laser printer that eliminates dirt and trouble since it’s a bundle of sleek and accessible gadgets, similar to what Cricut has done with craft cuts. It’s a medium Glowforge precision laser with a more robust Pro edition and a somewhat less powerful Basic model.

xTool D1 Pro-Best Laser Cutter

The xTool D1 Pro is a strong diode laser cutter with laser energy choices of 10W and 20W. It has a work surface of 430 × 390 mm and can accommodate workpieces up to 2 mm thick. The xTool D1 Pro is made entirely of weight and metal, approximately 11 pounds. Moreover, the D1 Pro’s steel timing pulleys and full aluminium plates allow it to attain a high cutting precision of roughly 0.004 inches.

Ten-High Upgraded Version CO2

The Ten-High Improved Version CO2 is the ideal laser cutter for most customers since it is very powerful and reasonably simple to operate. It could cut through a broad range of materials. However, it should be noted that it will not cut into the metal.

ORTUR Laser Master 2

This low-cost laser cutter might appear to be a daunting concept at first, coming as a jumble of pieces that could leave you asking what on earth you have gotten yourself into. However, after you’ve completed the simple assembling procedure, you will immediately realize you’ve got a firmly competent cutter on your hands and a wonderful one for the amount you spent.

Triumph Fiber Laser Cutting Machine

Triumph Fiber Laser Cutting Machine is designed for metal, making it an excellent option for engraving. A high-speed galvanometer enables you to cut silver, gold, copper, stainless steel, and aluminum without shadowing. With assistance and a touchscreen, the UI is pretty straightforward to utilize. It also includes pre-installed applications, allowing you to get straight to work.

Conclusion

Precision laser services are a kind of engraving and cutting that uses highly concentrated pressure and energy. This capacity allows for more accurate cutting on tiny surfaces. Laser cutting accuracy also saves material by dramatically reducing heat waste and unused junk material. In addition, lasers could carve delicate and complicated structures since the laser’s tip is highly concentrated and small. The outcome of precision laser services also includes clean edges and detailed finishing.